|

surfresearch.com.au

renwick : foam plastic board, 1958 |

| home | catalogue | history | references | appendix |

|

A photocopy of this

article was contributed by Mick Kershler, Anna Bay, October 2008, with

many thanks.

In 1953, Bill Reid

suggested a method whereby the blank was first covered with muslin cloth

between two coats of a plastic sealer before fibreglassing with standard

resin.

See:

1953 Bill Reid

: Fun on a Plastic

[Styrofoam] Surfboard.

Popular Mechanics

Magazine July 1953 Volume 100 Number 1 pages 157-159.

This method was employed by some New Zealand surfboard builders in the 1950s-early 1960s, as balsawood and polystrene blanks were difficult to obtain due to import restrictions.

Stryofoam, or Coolite,

in combination with expoxy resin was used for a short time in Australia

by McDonagh Surfboards in the late 1950s.

The styrofoam-epoxy

combination may have also been used by some American manufacturers.

The method became

an accepted manufacturing method beginning around the mid-1990s, following

years of intensive and expensive development by sailboard manufacturers,

now comonly called epoxy boards

HOW TO BUILD A

foam

plastic SURFOARD

|

Here's a plan

you've all been waiting for.

Building this surfboard is so simple that Grandma could do it. Cost won't be a problem either! |

Eight feet is

the recommended length for the board, but if you weigh over 13 stone it

would be wiser to make it nine.

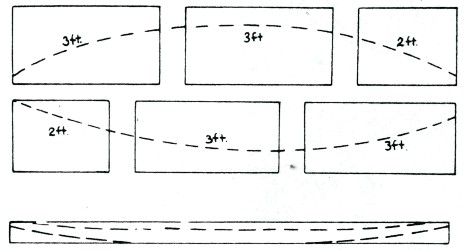

Cut one ft. each

off two of the Coolite blocks and glue them together with Epoxy Resin so

that the glued together Coolite measures eight ft. by two ft.

Stagger the small

blocks of Coolite so that no single join extends right across the board.

Once the board

is glued together .the top shape can be cut out.

The width of the

board should be about 22 in.

The Coolite should

be shaved away at the nose, from the underneath, and starting from about

three ft. back.

The edges of

the board at the nose should be very narrow, towards the centre they should

be rounded and at the tail quite narrow, though not as narrow as at the

nose.

Like the nose

of the board, the tail should cut away from underneath until right at the

tail it is about 1 1/4 in. thick or less.

Coolite can be

shaped with a carving knife, or a bread knife.

It is extremely

easy to cut.

Cut out the top

shape and round the side roughly with a knife, finishing off with fairly

fine sandpaper. It is important that the finish should be smooth, and extra

work on the shaping will pay dividends in a much better final finish.

Once the shape is finished, the whole board should be covered with two coats of epoxy resin, which seals it from the chemical action of the normal fibreglass resin.

Now comes the

time for laying the fibreglass.

This can be bought

in lengths 54 in. wide.

It is laid in

the board and cut so that it completely covers one side with a few inches

hanging over to wrap around to the other side.

The resin is

applied with a brush, working from the centre of the board out to the edges,

and towards the ends.

Enough resin

is applied to completely impregnate the cloth.

Rather than put

all the little tips about fibreglass down here (they would be much too

confusing) have a talk with the fibreglas (sic) dealer from whom you buy

your materials.

Once you have

completely fibreglassed one side, apply resin to the overhanging pieces

which should wrap around neatly to the other side of the board.

Repeat this on

the other side and then sandpaper off all the rough pieces.

More resin is

now applied to get a glassy surface.

Fibreglassing

is very easing - there are no complicated processes- but a talk with the

dealer will cer- tainly be advantageous.

Use a thick brand

of fibreglass cloth for the job, and don't spare the resin.

After the fibreglassing is finished the fin should be placed about one inch from the tail, secured firmly with fibreglass.

|

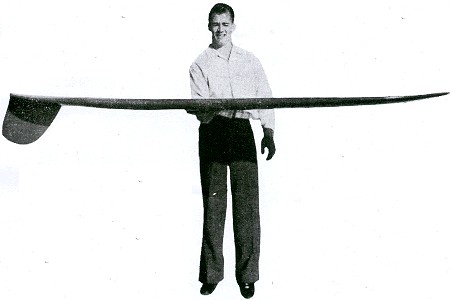

The boards

behind them are

|

|

|

such a way that no join runs the full width of the board. |

|

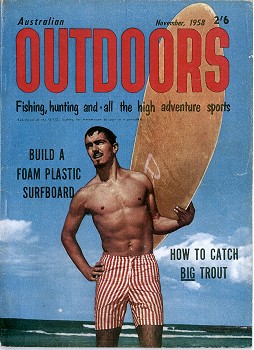

How to build a foam plastic surfboard. Australian Outdoors November, 1958, pages 11 to 12. This article contributed by Mick Kershler, with many thanks, October 2008. |

| home | catalogue | history | references | appendix |