|

surfresearch.com.au

obelian

: early big wave design history, 1989

|

|

Surfer,

Volume 30 Number 10, 1989,

pages 104-105.

Give

It

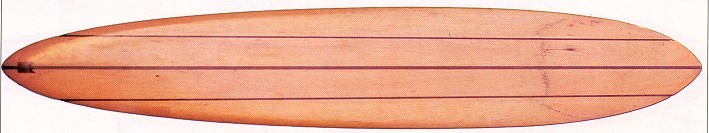

the AxeEarly Development of the Modern Gun by George Orbelian Board,

Axe and Knife

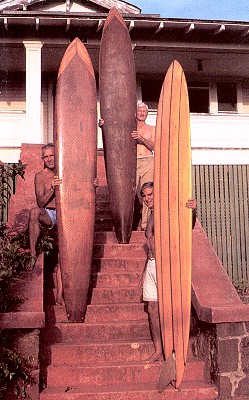

Photograph : Gary Lynch, page 104. |

|

During the

Summer

of 1936 Wally Froiseth, Fran Heath and John Kelly spent a frustrating

morning "sliding ass" (sliding tail/sideslipping) on their

square-tail

planks, in perfect 15-18' rights at Brown's surf near

Diamond Head.

They went home for lunch where, in frustration, Kelly grabbed an axe and took a calculated, slashing cut at the tail-rail of his board.

They shaped and blended the new, narrow vee-tail, and were back out at Brown's by 2:00 the same afternoon - the varnish still sticky.

Kelly caught his first wave, felt the narrow vee-tail bite, and shot across a wall just under the lip.

The narrow-tail gun was born, and named the Hot Curl.

They went home for lunch where, in frustration, Kelly grabbed an axe and took a calculated, slashing cut at the tail-rail of his board.

They shaped and blended the new, narrow vee-tail, and were back out at Brown's by 2:00 the same afternoon - the varnish still sticky.

Kelly caught his first wave, felt the narrow vee-tail bite, and shot across a wall just under the lip.

The narrow-tail gun was born, and named the Hot Curl.