surfresearch.com.au

|

surfresearch.com.au

sibley : surf sleds and

boards, 1928

|

Hi Sibley : Surf Sleds

and Boards, 1928.

Sibley, Hi:

Surf Sleds and Boards

Popular Science Magazine

Volume 112 Number 6, June 1928, pages

79 and 96.

googlebooks.com

(Thanks to Howard Fink, April 2010)

Googlebooks-

Hi

Sibley: Surf Sled and Boards, 1928.

Introduction.

This 1928

article in Popular Science Magazine

was

identified by Howard Fink as presented on

googlebooks, April

2010.

Many thanks to Howard.

Reprinted in

Wakeling, Arthur (editor): Home Workshop Manual; how to make

furniture, ship and airplane models ... sporting equipment.

Popular Science Pub. Co., New York, 1930, pages 340-341.

Hathi Trust

https://hdl.handle.net/2027/wu.89097361323

Page

79

|

Surf

Sleds

and

Boards

Simple

Ways to Build

Them

- One Type Is Only

a

Piece of Plywood, yet

It

Gives Thrilling Sport

By

HI SIBLEY

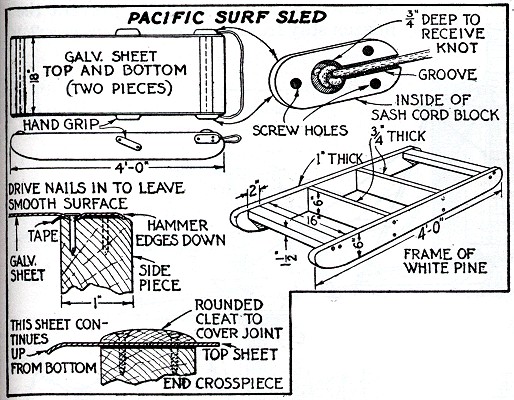

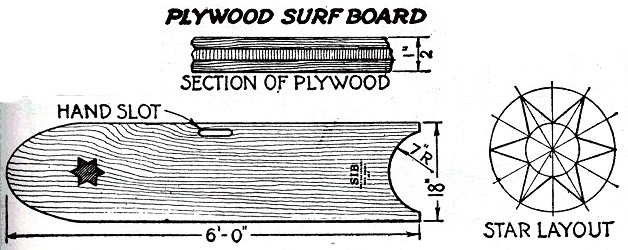

Fig.

1.

Most

successful

of the many varieties of surf

boards

used on

the breakers of southern California

is

this lightweigty

model made of plywood.

|

There

used to be a tradition that no one but a native Hawaiian could

ride a surf

board.

Young America,

expert in the sports of all nations, soon exploded that myth.

Now nearly

every

beach on the Atlantic and Pacific Coasts, as well as on the

Great Lakes,

has its devotees, some of whom have developed a fine skill.

Persistence

and

enthusiasm are required to master this exciting sport; it is

matter of

catching the right roller at right time- of climbing aboard

just the comber

is going over.

One can

learn

by practice better than by being told how to do it, but to

start with one

must have a suitable surf board or surf sled.

A sled

requires

a little more work to construct, but it will give the less

skilled or less

daring bather a sure-fire ride on the crest of the foam.

Both types

are

illustrated.

Surf boards

are

made in a large variety of styles to suit individual tastes,

but the one

which has proved the most successful on the breakers of

southern California

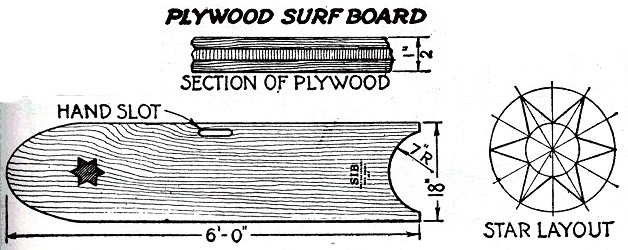

is the light plywood model shown in Fig. 1.

This

illustrates

a boy's size- about 4 1/2 ft. long.

A drawing at

the bottom of Fig. 3 shows how to make its adult prototype.

A plywood

board

is desirable because of its lightness and the fact that it

is not likely

to split or warp.

It may be

purchased

from any cabinetmaker and from many lumber yards.

A

three-layer

piece about 1/2 in. thick is satisfactory, although a

thicker piece of

five-ply wood will make a more substantial board.

Saw the

outlines

as shown with a good keyhole or turning saw.

A sharp saw

with

comparatively fine teeth is to be preferred, as there will

be less likelihood

of tearing the wood.

The hand

slot

is made by boring two 3/4-in. holes about 5 in. apart and

sawing out between

them. The slot is only for convenience in carrying the

board; it is not

used in the surf.

The rider

grips

the sides of the board where he can shift his grip or let it

go entirely

if disaster looms.

|

Fig.

2.

The

surf sled

can be used in any sea not too dangerous for ordinary

bathing.

The

rider holds

himself by the handgrips or lies flat on the

deck.

In

Fig. 3 is

shown a slightly improved design. |

It

is highly important to round off all sharp corners and edges

to prevent

cuts and bruises while in the turbulent surf.

You must also

give the edges several coats of spar varnish so there will be

no possibility

of the water's soaking in between the layers and loosening

them.

As the

plywood

usually has a beautiful grain, a natural finish with spar

varnish produces

the most

attractive

appearance.

First,

however,

paint in your star at the forward end.

Brilliant

vermilion,

or bright green with an out-line of gold, is effective.

On one board

the writer made a gold-leaf star with green border.

It is a good

idea to b put your initials and address at the lower end

of the board,

for anything as much in demand as a surf board has a

tendency to wander

from the home strand.

Because the

lower

end is cut to fit the body, the bather is able to walk out

facing the surf

and looking for an accommodating wave (Fig. 4).

When it

comes

he quickly swings the light board around and climbs aboard

for a swift

and merry trip.

Take great

care

that the nose of the board is always tilted up.

If it goes

down

and likes the sand, with a big breaker behind, painful

injury may result.

|

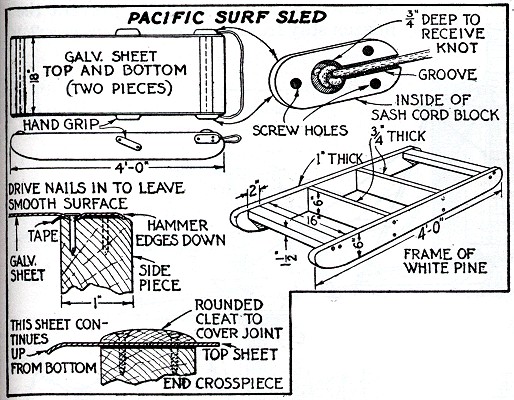

Fig.

3.

The

surf sled

is a frame of light white pine covered with galvanised

iron; the surf board

merely sawed from plywood.

(Images

adjusted) |

With a surf

sled

such as illustrated in Fig. 2 and the drawings in the upper

part of Fig.

3, the rankest amateur is guaranteed a successful,

hair-raising trip, provided

he once gets it out to the starting point.

Being

sufficiently

buoyant to support a heavy adult, the sled calls for little

skill except

in the matter of getting under way and has a great advantage

in that it

can be used successfUlly in much lighter surf than the surf

board.

It even can be

used as a float or raft in calm weather and will always be in

demand.

This type

of sled

is fairly light for a grown person to manage, but it is not

the thing for

a youngster to tackle, except in moderate seas, because of

the tremendous

force with which waves may strike it broadside.

Note that

all

edges and corners are rounded, so that if one has a spill

and is struck

by his mount, it will not leave any appreciable dents.

The vital

importance

of removing all protruding angles was learned after several

beginners had

become conspicuously bruised by screw eyes used in our first

model.

The proper

way

to maneuver the surf sled is to walk into the surf at right

angles, towing

the sled behind you by the sash cord provided for that

purpose.

It will

slide

over the oncoming breakers easily if the stern is lifted

slightly.

Use light

white

pine for the framework and fasten it with flat-head wood

screws, well countersunk.

The ...

(Continued

on page 98)

|

Fig.

4.

The

light plywood

surf board is easy to handle.

The

lower end

is cut so as to fit the body.

The

bather takes

this position when walking out into the surf. |

Page 98

(Continued

from page 79)

... ends

should

be rounded so that the galvanized sheet bottom can be carried

up around

them and fitted snugly at every point.

Have the top

and bottom galvanized sheets cut about 3/8 in. narrower than

the width

of the frame, so that there will be no possibility of their

protruding

and injuring the bather.

Likewise, the

corners of the sidepieces and handgrips must be rounded

smoothly.

Before

setting

the sheet metal, paint the edges of the side boards with

white lead and

lay a strip of muslin or electrician's tape the entire

length, taking care

that there are no folds or wrinkles.

Cover this

with

a coat of white lead.

Then fasten

the

galvanized iron with nails about 3/4 in. long, staggered

about 1 in. apart.

Drive them

in

well; then depress the edges of the metal into the wood

(Fig. 3).

The cleats

over

the places where the galvanized sheets join each other

should be drawn

down tightly with screws, but first nail the ends of the

sheets to the

crosspieces to make the joints water-tight.

Follow your

own

taste in painting and trimming; green with orange striping

is effective.

In any case,

be sure the first coat dries thoroughly before applying the

second.

Several

coats

of spar varllish will add to the life of the sled.

|

Sibley, Hi: Surf

Sleds and Boards

Popular Science Magazine

Volume 112 Number 6, June

1928, pages

79 and 96.

|

surfresearch.com.au

Geoff Cater (2010-2017) : Hi

Sibley

: Surf Sleds and Boards, 1928.

http://www.surfresearch.com.au/1926_Sibley_PopSc_June_p79.html